Can production line in mixed sizes/instantaneous switch

Below are some examples of the products that Enami has developed.

We manufacture products that are suitable for various usages in wide industrial fields.

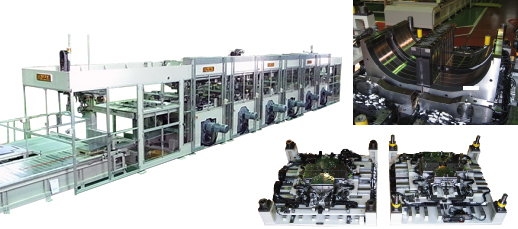

Outer appearance of the system and its dies

Needs from our customers

Customers need to reduce the time that the products are on the production line and in store and achieve significant reduction of delivery lead time. In order to realize this, they have to replace the lot system by which cans are produced one kind after another, with a production system that allows manufacture of mixed kinds of cans at the same time depending on orders.

Enami’s development solution

Enami has designed a production system for multiple kinds of cans, without the need for interfering on the line, with automatic instantaneous die changes. This production system for mixed kinds of cans allows the manufacture of cans even with the smallest lot size(one can).

Outline of the production line specification.

| Materials | Spec 1.2 t Possible both with coiled materials and cut materials in fixed sizes. |

|---|---|

| Product sizes and number of kinds | (L): 150 - 600 m/m (10 kinds) × (W): 150 - 600 m/m (10 kinds) × (H): 70 - 220 m/m (11 kinds) Total 1,849 |

| Production cycle time and die switching time | Press 20 sec ( Switching motor: Servo Motor) |

| Pressing system | Under Drive System 1st Process: 60ton press, 2nd Process: 100ton press, 3rd Process: 100ton press, 4th Process: 60ton press, 5th Process: 80ton press, 6th Process: 80ton press |

| Footprint and height of the whole equipment | (L): 23M x (W): 30M (??) x (H): 3M |