An automated production line for stainless steel drums

Below are some examples of the products that Enami has developed.

We manufacture products that are suitable for various usages in wide industrial fields

Needs from our customers

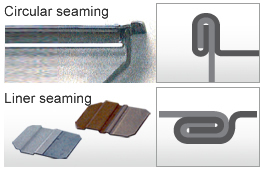

In latter years, the demand for products made with stainless steel is increasing. In order to respond to this, we would like to produce tumble drums for fully automatic washing machines with stainless steel. However, there is a big problem that we expect in implementing this by previously used methods, which involve joining materials by welding: it creates the need for numerous finishing processes after it. We would like to introduce a production line for stainless steel drums without the need of finishing processes.

Enami’s development solution

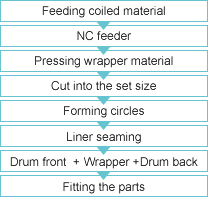

Enami has developed a totally automated production line in order to greatly reduce the number of processes and to ensure uniform product quality. For joining the materials, we have replaced the welding process by freely using caulking technologies, in which we have strength and long experience.

Outline of system specification

| Product Materials | Drum Front: SUS 0.4 - W0.8t Wrapper: SUS 0.6 - 0.8t Drum Back: 0.4 - 0.8t |

| Product size | (Diameter) ?473 – ?562.8mm (Height) 215.5~424.9mm |

| Manufacturing Processes |

|

| Production cycle tim |

25 seconds |

| Footprint and height of the whole equipment |

(L): 17M x (W): 7M x (H): 3M |

Finished product