Only ENAMI can provide the equipment “lath sheet production equipment”

For lath-sheet-processing, this machime starts with coil sheets, and perform press-forming using automatic feeder.

Idle equipment can be used.

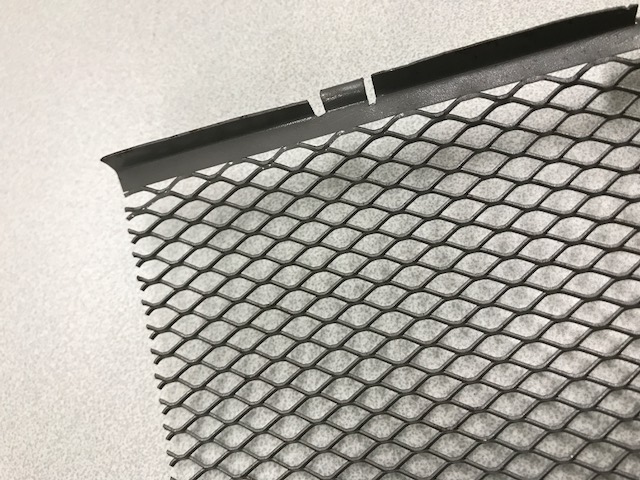

What is lath sheet?

Originally, it is a type of construction member, which is fabricated by

For this reason, this is also called expanded metal lath or expanded metal.

feature

“Beard”does not come out in processing.

“Beard” is string-like scrap.

lath sheet prosseced completed parts are fabricated of coil sheet.

Only ENAMI can provide

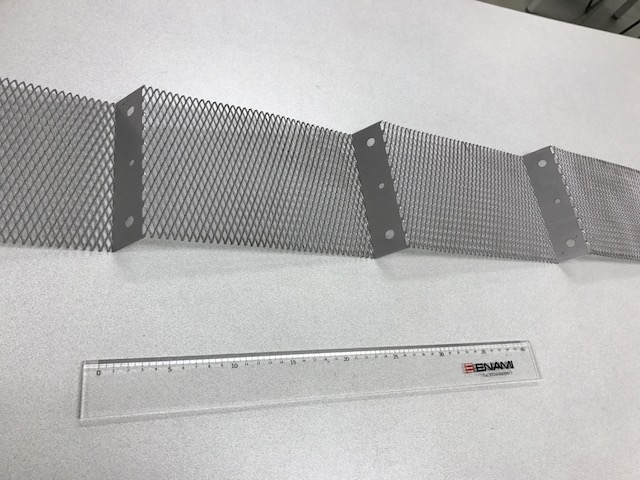

This machine can manufacture a product united with outer edge without ment.

The conventional machine fabricated the edge of perimeter sepratatory and weld it.

Specification

| line tact time | 5sec(26 steps) |

|---|---|

| line length | 5,550mm |

| structure | Uncoiler-leveler, NC roll feeder, 45t press, Transfer multiple joints robot, 20t press |

Machine photo

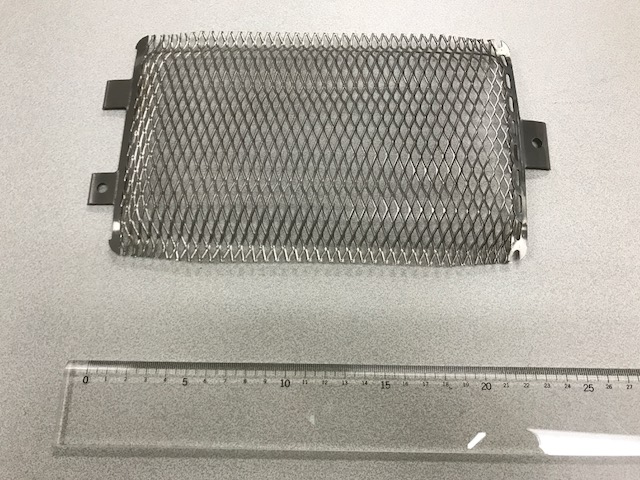

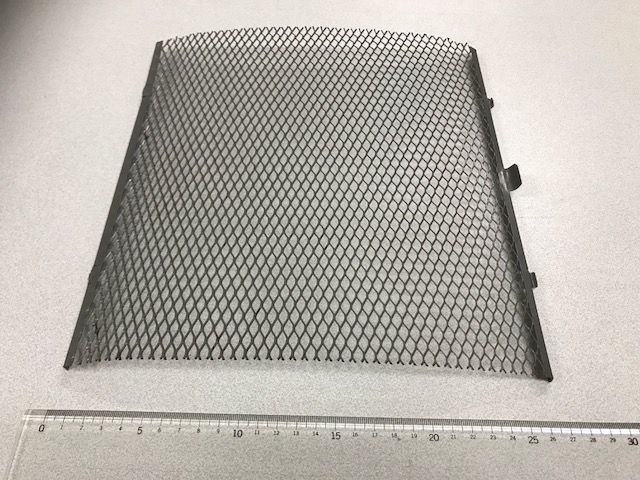

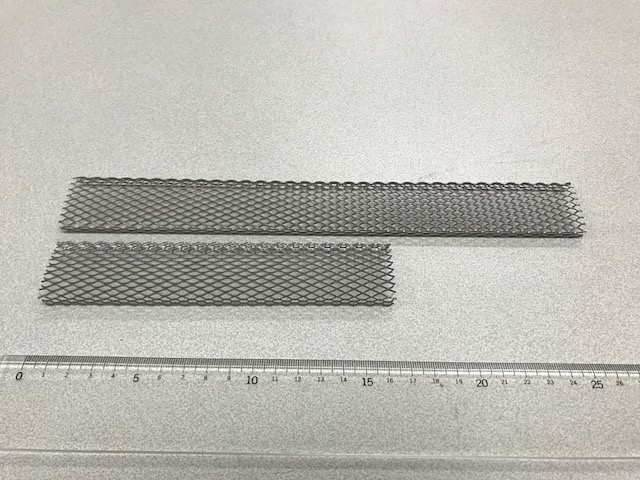

Product photo

We can suggest a system which meets the various lath sheet.