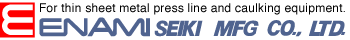

”Sirocco fan production equipment”dramatically decreasing the number of parts

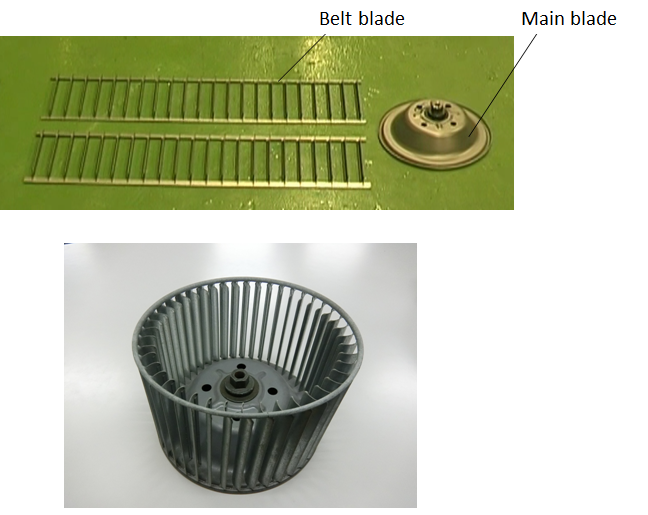

This machine curls 2 blades, and seam a main plate to form them into fan shape.

This maxhine can produce 4 types of fans.

(Blades and main plate is formed by different dies,)

Machine overview

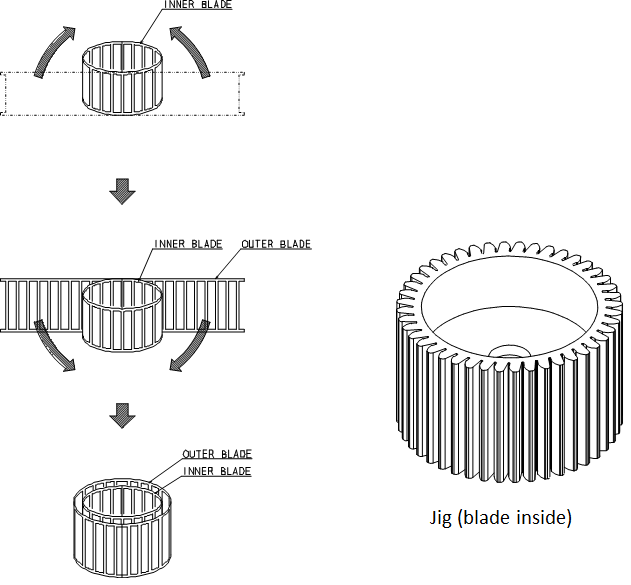

this machine winds 2 blades onto the jig, curls them, and seam the main plate automatically.

Positioning workpieces (2 connected blades and a main plate ) is manual outside the the machine.

Specification

| Application | Sirocco fan |

|---|---|

| Capability(Cycle time) | 40sec |

| Diameter | φ150、180、200、230mm |

| Height | 98、118、128mm |

| Thickness |

0.4+0.8、0.4+1.0、0.4+1.2 0.5+1.0、0.5+1.2mm (t0.4、0.5mmはブレード) |

feature

①conventional product:insert the single blade into the ring shape part,and caulk them

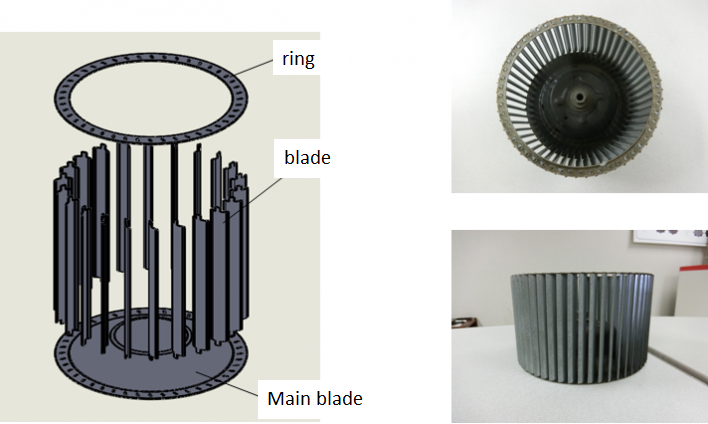

②ENAMI PLAN:change a single blade to 2 band shape blades comprising multiple blades.。

processing stage

①positioning workpiece: Curl the band shape blade in

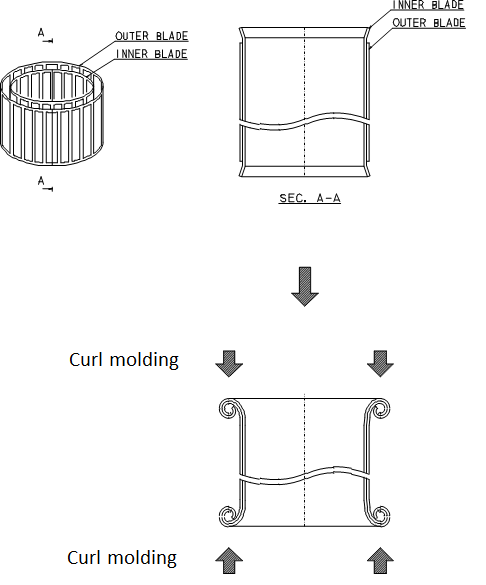

②Curl forming 1:Curl the upper and lower face

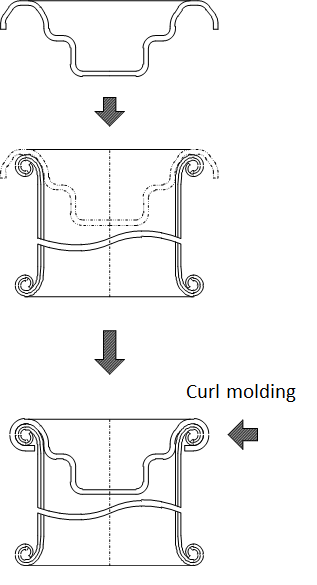

③Seam forming 2:Seam the main plate

Watch the motion video