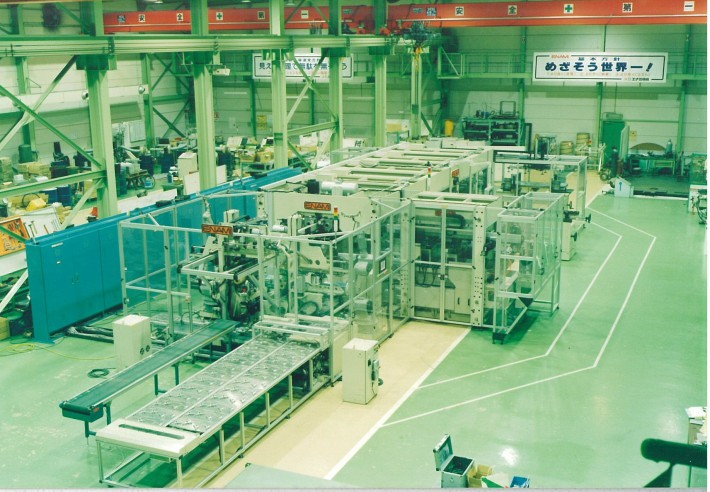

A production line for the outer bodies of fully automatic washing machines

Below are some examples of the products that Enami has developed.

We manufacture products that are suitable for various usages in wide industrial fields.

External appearance of the system

Needs from our customers

Abolishing the conventional welding and painting processes, and, by using coated steel sheets, customers demand shortening of the process and production lead times. Further more, the time necessary in between for changing the colour of the outer body should be reduced. The production line should also help to protect our environment preventing air and water pollution.

Enami’s development solutions

Using PCM steel sheets and joining the materials by calking instead of welding, Enami has established a process (pressing process) for making the outer frame without scratching the outer surfaces. Enami also has achieved a production line that produces two entirely rounded forms with different degrees of curvature by changing dies automatically without the need for interference during the production.

Comparison between Post Coat (Old) & Pre Coat (New) methods

→ Production cost 20% less

| Without using coated steel sheets(postcoat) A |

Using coated steel B | B/A(%) | |

|---|---|---|---|

| Operators | 12 persons | 2 persons | 17 |

| Lead time | 164 minutes | 1.3 minutes | 0.8 |

| Production cycle time | 28 sec | 12 sec | 43 |

| Interference | 41 min/time | 5 min/time (replacing 12) | 12 |

| Space necessary for the | 3.225m2 | 225m2 | 7 |

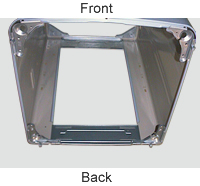

A finished product and the appearance of the shape of the product

|

|